DOs and DON’Ts of Hydrated Lime (HL) in Asphalt Mixtures

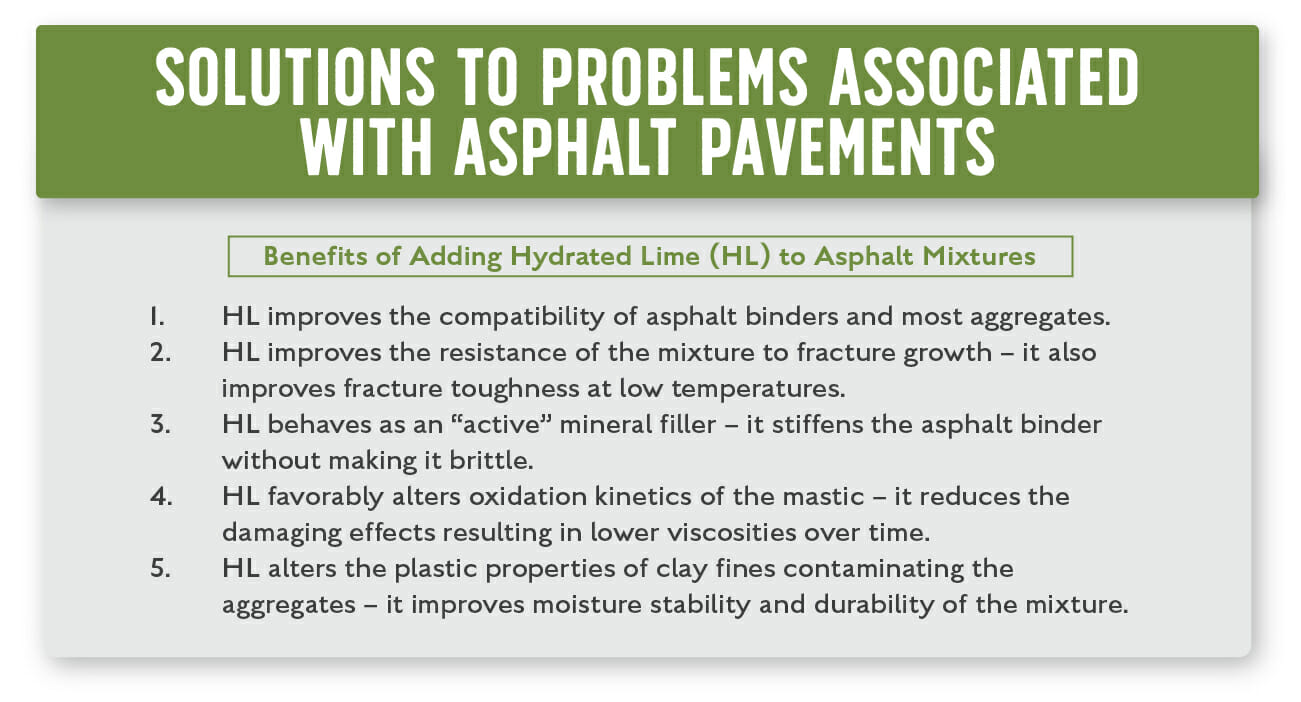

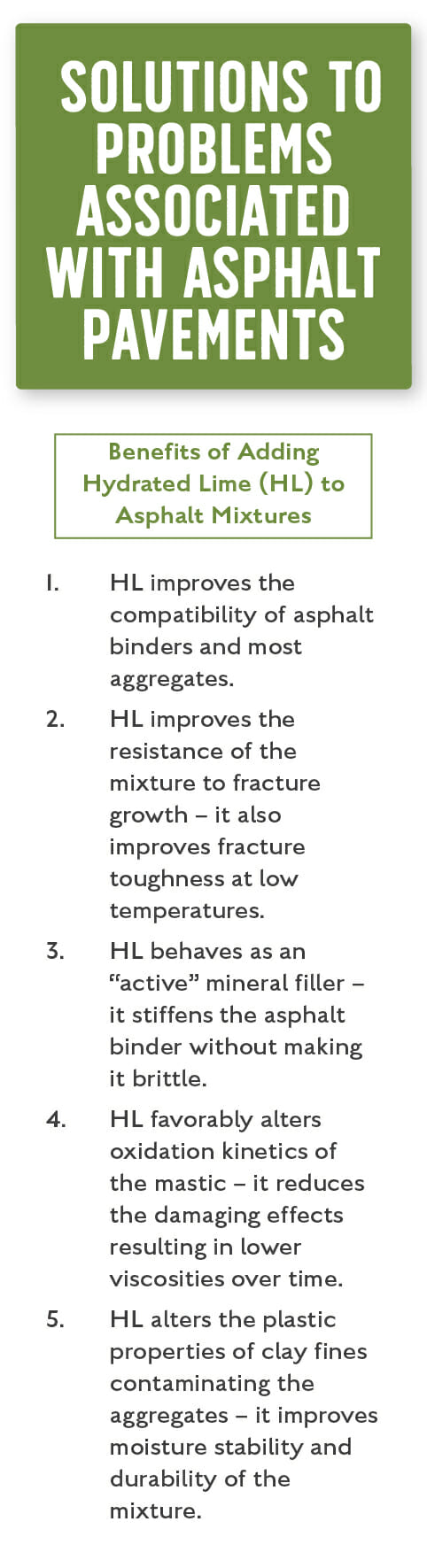

Benefits of Adding Hydrated Lime (HL) to Asphalt Mixtures

1. Always use “hydrated lime” (HL) to produce high-performance mixes. Don’t use “quicklime” as it will damage the mixes. Don’t use “agricultural lime” since it consists of non-reactive limestone. Don’t substitute by-products for chemical grade HL since their composition is variable.

2. Always use fresh HL in test and field mixes. Always store HL in airtight containers or silos. Don’t store HL for more than 6 months. The lime will oxidize and revert to limestone.

3. Always add HL based upon the total weight of the mixture.

4. Always determine the addition rate of HL based upon results from tests such as Hamburg Wheel Tester, Lottman tensile strength ratios, or other “performance” tests. Optimum HL percent will vary based upon aggregate composition, binder compatibility and/or mix design.

5. If moist aggregates are specified to ensure that HL adheres to the stone always shoot for 3-5% surface moisture.

6. Always use a pugmill or belt plows to blend the HL with the aggregates.

7. If HL is added directly to the drum always ensure that the addition location is immediately before (and close to) the point where the asphalt binder is added.

8. Always add HL in using a method that maximizes aggregate contact and/or intimate binder exposure.

9. Always select an addition method that will distribute the HL evenly throughout the mixture.

10. Always check the calibration and operation of the HL delivery system before every shift.